For thousands of years, the only way to power tools was with human hands. As the centuries progressed, tools became more efficiently designed to function better, but still required the touch of man. Within the last two hundred years, that began to change as man began to invent new ways to power tools, taking them out of our hands, making them faster and more accurate. Yet, there has always been a place for hand tools in our work. As late as the 1970’s Journeymen Carpenters were expected to have a large assortment of hand tools in their inventory. But the last two decades of the 20th century saw an upsurge in power tool use. If you didn’t have a full collection of power saws, drills, routers, sanders, shapers, etc, you weren’t a real woodworker.

For thousands of years, the only way to power tools was with human hands. As the centuries progressed, tools became more efficiently designed to function better, but still required the touch of man. Within the last two hundred years, that began to change as man began to invent new ways to power tools, taking them out of our hands, making them faster and more accurate. Yet, there has always been a place for hand tools in our work. As late as the 1970’s Journeymen Carpenters were expected to have a large assortment of hand tools in their inventory. But the last two decades of the 20th century saw an upsurge in power tool use. If you didn’t have a full collection of power saws, drills, routers, sanders, shapers, etc, you weren’t a real woodworker.

Fast forward into the 21st century, when jet packs and flying cars were to have been the norm, and there is a resurgence of hand tool use. The number of companies making hand tools has increased, and with the influx of inexpensive tools from overseas, they are available to any budget.

But what accounts for this return to our ancestral heritage? Certainly, power tools get the work done far faster and more accurately. Why would anyone in their right mind want to sweat over a hand plane, smoothing rough sawn stock for use in projects when you can buy wood ready milled from the home improvement centers? As with anything, I don’t believe the answer is simple, or that there is one answer. Over the last few years I have developed some reasoning of my own for the switch, and have communicated with many other woodworkers who are getting off the grid either totally or partially. Here are some of the reasons I have come across.

Nostalgia. It is a common trait of man to look back to “the good old days” with fondness and longing (often forgetting the not so pleasant parts of years gone by). In my earlier years I spent a lot of time as a Living Historian, outfitting as someone from the past, and giving talks at historic sites to folks from all over the world. Doing this I got to see the fascination first hand…we all like to think of the times of our fathers as better than ours. So we love to hear about those times, to see them brought back to life, and, for the more adventurous of us, to dive in and do some things the way our grandparents did. Whether woodworking, or baking, or sewing, it gives a satisfaction to connect with our past in this way.

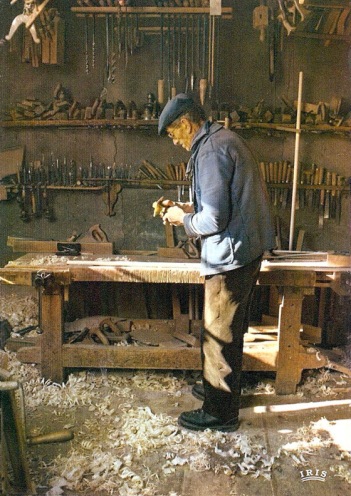

I can’t easily describe the personal thrill of handling one of my wood bodied planes from the 1800’s. To feel it glide effortlessly through the wood, to marvel at its simple, yet very well thought out design. It’s very easy for me to see how this method of work would appeal to some folks.

Health Concerns. This was a big one with me, and from what I’ve read online, I am certainly not alone. As I’ve gotten older, I find that I cannot tolerate the fine dust spewed out by most power tools. And the obvious solution of wearing a dust mask is not as effective as I need, nor is it very comfortable. Hand tools create virtually none of the microscopic dust particles so prevalent with power tools. The debris left behind hand tool work is generally either wood shavings or large granules of saw dust, both too big to become airborne or be inhaled.

Another aspect of hand tools over power tools is the noise level. Power tools are fed by high speed electric motors, putting out high pitched whines at high decibel levels. The constant exposure to this noise can be very damaging to your ears. Of course, there are ear muffs and ear plugs. But I find they tend to disconnect me somewhat from my surroundings, which can be dangerous if I miss an important sign of a machine about to fail, or something about to fall. Add to the fact they are just damn uncomfortable.

When I am in my hand tool shop, I can listen to the radio or TV without interruption. The noise level is so low as to be almost unnoticeable (my wife in the next room often does not know that I am working, it’s so quiet). And even if I am banging on a chisel or driving a peg home, the noise is still different, still far less offensive.

Economics. Woodworking is one of those pass times that attracts people from all walks of life. For those of us on the lower end of the socio-economic strata, equipping out a power tool shop with all the bells and whistles is not always possible. Hand tools are an excellent way of supplementing operations in your shop without going deep into debt. For instance, to buy a mid level 6 inch jointer and a lunch box thickness planer will set someone back $800 plus. But, a set of hand planes to do the same job can be had for under $300, a considerable savings. Granted, not as fast as their powered versions, and a higher learning curve, but they can also do more than power tools. Ever try to joint an 8 inch board on your 6 inch jointer? I have face flattened stock 12 plus inches wide, taking out twists and cups so it can be run through a thickness planer (yeah, I got one of those, see below). So even if someone doesn’t intend to replace power tools with hand tools, they may think about using the hand tools as supplements. Often they are easier to use for some operations, and sometimes they are the only way to perform some operations.

Space. I saved this one for last as it’s a special one for me. My initial work area was the front third of my garage, 22 feet wide but only 6 feet deep. There was very little room for a lot of power tools. My main power tool has always been my fathers 1952 Craftsman bench saw, which takes up about a third of the floor space available. Throw in a work bench or two, plus storage for wood and consumables, and maybe a small dust collector for the saw and an ancient drill press, and it’s getting mighty tight in there. I literally had no room at all for a jointer. Try as I might, I just could not fit it in. The solution? Hand tools. I had long ago purchased a trio of old bench planes that worked very well, from a small smoother to a long jointer. These three planes let me flatten a face and true an edge to that face pretty quickly, and required no more storage space than a drawer in my bench.

I have heard from numerous wood workers who live in apartments or condos, whose neighbors and landlords would have a cow if they were to crank up power tools in their apartment. Not to mention the dust, and the weight involved. It is just not practical by any stretch. So, are these urban craftsmen to do without? Are they forbidden from the craft solely by merit of their habitat? Not at all. These clever folks set up wonderful spaces in spare rooms decked out with all the hand tools needed to turn out masterpieces of wood construction. And their neighbors are none the wiser.

A plug for power tools. So, does all this mean you should scrap your power tools and run out to buy the latest hand tool? That depends. It depends on you, on what you are trying to accomplish.

If your aim is to use woodworking as a hobby, as a form of relaxation to calm your nerves and expand your knowledge, then maybe. This type of woodworking is generally more appropriate for hand tools. This is simply because of a. The time it takes to make something, and b. The learning curve.

Making something by hand, whether it’s a low boy or a loaf of bread, takes longer. It’s the nature of the beast. Writings from wood shop owners in the late 19th century bemoan the machine powered shop, simply because they were faster. Many customers did not want to wait months for their bedroom set. Even so, some modern woodworkers make a comfortable living making furniture by hand. But, they are very good at what they do, and their furniture is worth waiting for.

Hand tool work is also harder to learn. Because the quality of work is based solely on the interaction between the human hands and the tools, it is practice makes perfect in the extreme. Why do you think the average apprentice joiner took seven years before he was good enough to go it on his own? Power tools, on the other hand, do more of the work for us. They are designed to be more accurate, so the main thing we have to learn is set up and feeding. The machine does the rest. When I first started, I was totally power tool equipped. I learned everything I needed to get started from books, even picking up advanced techniques by reading articles. And although using hand tools can be learned this way, there are often nuances to technique that can only be passed on by a teacher standing over you, making sure you are doing it right. This has been my experience, at least.

So again, the answer is Maybe. If you really want to learn to use hand tools, or the dust and noise are harmful to you, or you can’t afford or have the room for power tools, or you want to do something that there isn’t a machine way of doing it, then hand tools are definitely the way to go.

Postscript. I developed my desire to learn hand tool work during my days as a living historian. I was, and still am, fascinated with how even simple things were accomplished by our ancestors. Still, as I mentioned, I do own power tools. With my health problems with dust, I use fewer of them than I used to. Many are gathering dust themselves. Nowadays I use my table saw for ripping, and a thickness planer to thin stock, or to make the second face parallel to the one I just hand planed. My main reason for using these last two vestiges of the machine world are a. Speed, I’m still somewhat impatient when working on a project, and b. The learning curve. I am getting better at ripping and thicknessing by hand, but I’m not there yet. I expect, however, that neither the table saw nor the planer will be replaced when they finally give up the ghost.

As a follow up to the above, I recently came across a blog article from Bob Lang, one of the senior editors at Popular Woodworking Magazine. Bob has yet another use for hand tools, in conjunction with power tools. Read his blog at http://www.popularwoodworking.com/techniques/hand-tools-techniques/whatplanesaregoodfor

Hello,

Very timely to come across your good article. Just this week I have begun to put machines, five years now in storage, back into use. Over those past years I have been restoring the old farmhouse here along with renovating the barn to house my workshop, strictly using hand tools, often beginning with wood still in stem form. Perhaps another reason to add to your list, necessity to get stuff done regardless.

Regards,

E.DB.

LikeLiked by 1 person

That sounds like a great long term project, Ernest, bringing your barn back to life using the type of tools that built it in the first place. It’s work like that that gives us our greatest satisfaction when completed. May you have many hours of pleasure in your new shop!

LikeLike

Reblogged this on Menuiserie Ebénisterie des Yvelines.

LikeLike